Precast Concrete

Our precast facility produces precision-made concrete panels in a controlled environment, resulting in shorter curing times and a superior, quality finish.

Streamlined Construction

By manufacturing prefabricated concrete panels in-house, we can prepare and store them ahead of schedule and deliver in time for installation. This minimises on-site delays, improves efficiency and speeds up project completion without compromising quality.

How Precast Delivers More

Precast concrete panels gives you speed, precision and long-term durability. Faster production and coordinated delivery keep your project moving, while superior dimensional accuracy ensures a perfect fit during installation. Every panel offers consistently high-quality finishes, strong acoustic insulation and long-lasting durability. Plus, it’s a sustainable, energy-efficient solution that requires minimal maintenance over time.

Architecturally Detailed Panels

In-house production expands what’s possible in both structure and design. Our precast panels can incorporate decorative joints, inlay patterns, polystyrene casts and form liners to create distinctive façades and architectural detail. From timber-look textures to exposed aggregate and polished concrete finishes, we tailor each panel to suit your project vision without compromising structural performance.

Design & Finishes

-

Form Liner Wood Finish

Timber grain moulds mimic real wood giving projects a softer, natural look

-

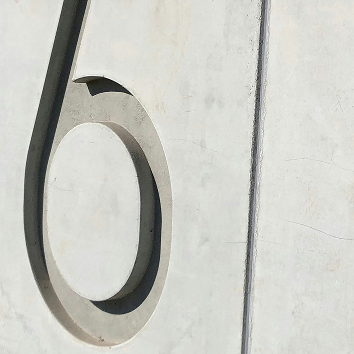

Decorative False Joints

Built-in joints add visual depth without affecting strength

-

Inlay Patterns

Patterns, numbering and text are cast into the panel for easy identification and custom styling.

-

Inlay Signage

Logos or text are embedded during casting to create durable, maintenance-free branding.

Common Applications

-

Structural Walling

-

Cladding

-

Retaining Walls

-

Soundproofing / Noise Barriers

-

Civil Works